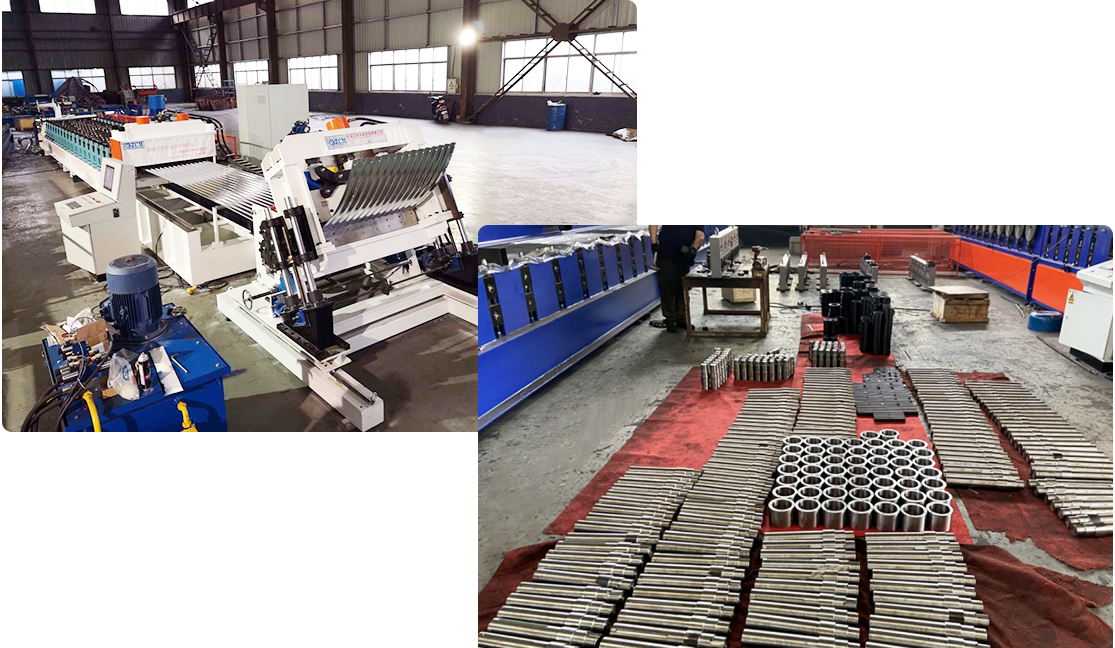

- Make It for Your Needs and Your Market

- Multiple offices

- Our service and support

We can give customer the samples of the end products. We also match some quick-wear parts to the machine in the first time for free. Generally speaking, our delivery time is about 45 days after the customer pay the down payment.After the machine is finished in our factory, we will ship the machine to te customer. We will dispatch the engineer to help the customer for installation and do commissioning and train the worker until the machine runs well.