Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 25, 2024 Visit:209 Source:ZCM Roll Forming Machine

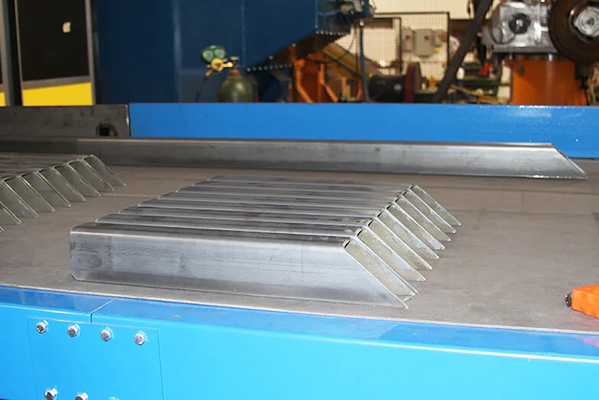

In the dynamic landscape of manufacturing, heavy gauge roll forming equipment has emerged as a versatile and indispensable tool, finding its way into various industries and applications. This technology, which involves shaping metal sheets into desired shapes and profiles through a series of rollers, has seen its applications expand significantly, catering to the diverse needs of multiple sectors.

One of the primary industries benefiting from heavy gauge roll forming equipment is the automotive sector. Car manufacturers rely on this technology to produce critical components such as frames, structural supports, and body panels. The precision and strength provided by roll-formed parts are crucial for ensuring the safety and performance of vehicles. Additionally, the ability to produce large volumes of components quickly and efficiently makes heavy gauge roll forming an ideal choice for the automotive industry's high-volume production needs.

In the construction industry, heavy gauge roll forming equipment is used to create structural elements like beams, columns, and roofing panels. These components are essential for the stability and durability of buildings and infrastructure projects. The strength and dimensional accuracy of roll-formed steel make it an ideal material for withstanding the rigors of construction and long-term use. Moreover, the ability to customize shapes and sizes according to specific project requirements enhances the versatility of heavy gauge roll forming in construction.

The aerospace industry also leverages heavy gauge roll forming technology to produce lightweight yet robust components for aircraft. These components, such as fuselage sections, wing frames, and landing gear assemblies, must meet stringent safety and performance standards. Heavy gauge roll forming enables manufacturers to achieve the necessary precision and strength while optimizing material usage and reducing overall weight, which is crucial for improving fuel efficiency and reducing operational costs.

Beyond these traditional industries, heavy gauge roll forming equipment is also finding its way into emerging sectors. For instance, in the renewable energy field, roll-formed steel is used to construct wind turbine towers and solar panel mounting structures. The durability and corrosion resistance of roll-formed steel make it well-suited for outdoor applications and harsh environments.

In the agricultural industry, heavy gauge roll forming equipment is used to produce equipment such as tractor frames, silos, and storage bins. These components must be able to withstand the rigors of farming operations and exposure to the elements. The strength and versatility of roll-formed steel make it an ideal choice for agricultural applications, ensuring the reliability and longevity of equipment.

Furthermore, the furniture and appliance industries also utilize heavy gauge roll forming technology to produce sturdy and aesthetically pleasing products. From office desks and shelves to refrigerators and washing machines, roll-formed steel provides the strength and durability needed to meet consumer expectations while optimizing production costs.

In summary, the applications for heavy gauge roll forming equipment have expanded significantly across various industries. From automotive and construction to aerospace and renewable energy, this technology offers a versatile and efficient solution for producing high-quality components. As industries continue to evolve and diversify, heavy gauge roll forming equipment will undoubtedly play an increasingly important role in meeting their manufacturing needs.