Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 25, 2024 Visit:256 Source:ZCM Roll Forming Machine

The heavy gauge roll forming equipment market has recently experienced a notable surge in demand, driven by a combination of factors that are shaping the manufacturing landscape. This increase in demand underscores the importance of roll forming technology in various industries and highlights the evolving needs of manufacturers seeking to enhance their production capabilities.

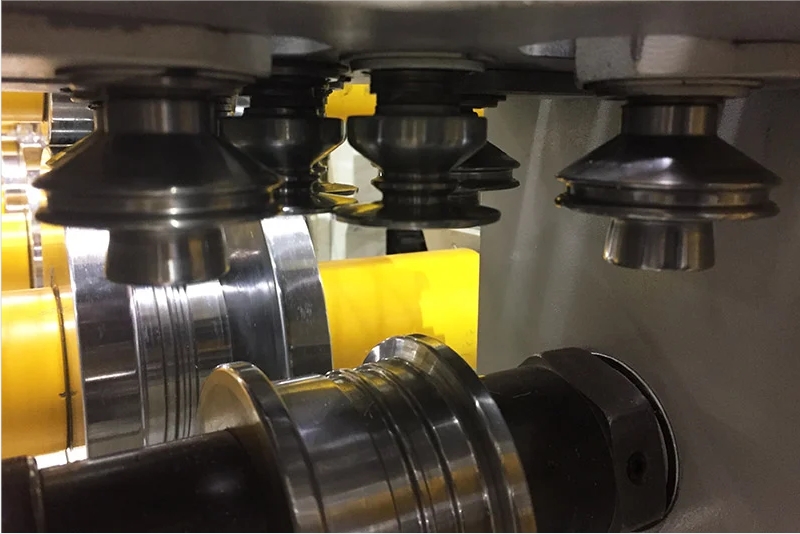

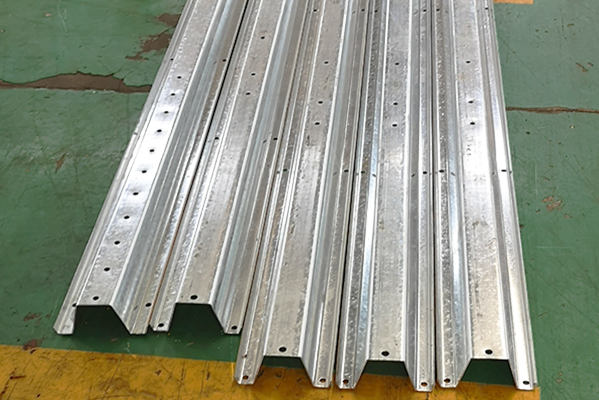

One of the key drivers behind this surge in demand is the growing emphasis on precision and efficiency in manufacturing processes. Heavy gauge roll forming equipment is renowned for its ability to produce high-quality, precise components with minimal waste. This makes it an ideal choice for industries such as automotive, aerospace, and construction, where precision and reliability are paramount.

The automotive industry, in particular, has been a significant contributor to the increased demand for heavy gauge roll forming equipment. As car manufacturers strive to improve fuel efficiency and reduce emissions, they are increasingly turning to lightweight materials such as high-strength steel and aluminum. Heavy gauge roll forming equipment is well-suited to processing these materials, enabling manufacturers to produce lightweight yet durable components that meet stringent safety and performance standards.

In addition to precision and efficiency, the versatility of heavy gauge roll forming equipment is another factor driving its demand. This equipment can be customized to produce a wide range of shapes and sizes, making it a versatile tool for manufacturers across various industries. From intricate automotive parts to large-scale structural components for buildings, heavy gauge roll forming equipment offers the flexibility to meet diverse manufacturing needs.

The surge in demand for heavy gauge roll forming equipment is also being fueled by advancements in technology. Innovations in automation, control systems, and software have significantly enhanced the capabilities of roll forming machines. These advancements have led to improved accuracy, increased productivity, and reduced downtime, making heavy gauge roll forming equipment an even more attractive option for manufacturers.

Moreover, the global economic recovery has played a role in boosting the demand for heavy gauge roll forming equipment. As economies rebound from the pandemic, manufacturers are investing in new equipment to expand their production capacity and meet growing consumer demand. Heavy gauge roll forming equipment, with its ability to produce high-quality components efficiently, is well-positioned to capitalize on this trend.

The increased demand for heavy gauge roll forming equipment is also reflected in the market dynamics. Manufacturers are competing to offer innovative solutions that meet the evolving needs of their customers. This competition has led to advancements in equipment design, materials, and production processes, further enhancing the appeal of heavy gauge roll forming technology.

In conclusion, the heavy gauge roll forming equipment market is experiencing a surge in demand due to a combination of factors, including the emphasis on precision and efficiency in manufacturing, the versatility of the equipment, advancements in technology, and the global economic recovery. This increase in demand underscores the importance of roll forming technology in various industries and highlights the evolving needs of manufacturers. As these trends continue to shape the manufacturing landscape, heavy gauge roll forming equipment is poised to play a crucial role in meeting the challenges and opportunities of the future.