Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 08, 2024 Visit:238 Source:ZCM Roll Forming Machine

In the realm of manufacturing, the efficient use of materials is a cornerstone of profitability and productivity. One critical area where material utilization can be significantly enhanced is in the realm of heavy gauge roll forming equipment. These sophisticated machines have undergone substantial innovations, allowing manufacturers to maximize the yield and quality of their products while minimizing material waste.

Precision Engineering for Optimal Shapes

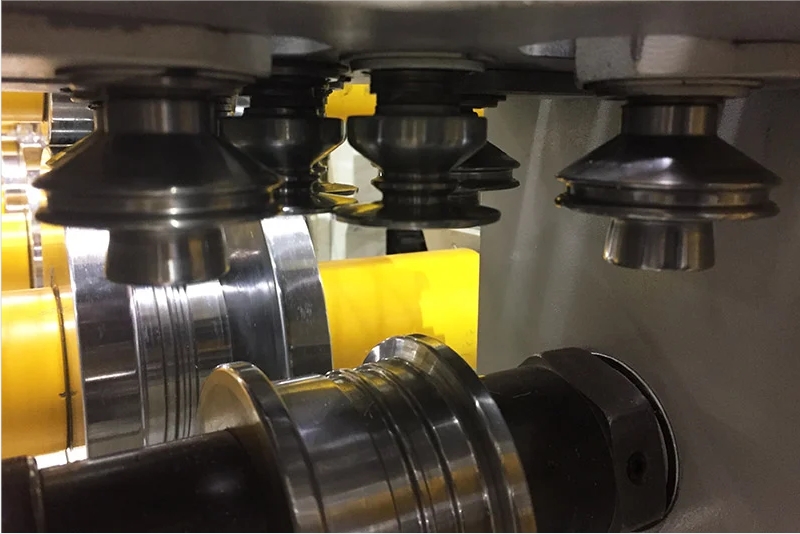

One of the key ways heavy gauge roll forming equipment optimizes material utilization is through precision engineering. Modern roll forming machines utilize advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to create rolls that produce exact shapes and dimensions. This precision ensures that each piece of material is formed to the specifications required, minimizing the need for secondary operations and reducing waste.

Furthermore, the design of the rolls themselves has evolved to be more efficient. The use of high-strength materials and sophisticated rolling techniques allows for the production of complex shapes without compromising the structural integrity of the material. This results in fewer defects and a higher percentage of usable product from each batch.

Adaptability and Flexibility

Another critical aspect of heavy gauge roll forming equipment is its adaptability and flexibility. Modern machines can be configured to produce a wide range of shapes and sizes, allowing manufacturers to respond quickly to changes in market demand. This adaptability reduces the need to maintain large inventories of prefabricated parts, which in turn reduces material waste and inventory costs.

Furthermore, roll forming equipment can be equipped with adjustable roll gaps and variable crown profiles, allowing manufacturers to fine-tune the forming process for different materials and thicknesses. This capability ensures that the material is utilized as efficiently as possible, regardless of the specific application or product requirements.

Waste Reduction Through Automation

Automation has also played a significant role in optimizing material utilization in heavy gauge roll forming. Modern machines are equipped with sensors and control systems that monitor the forming process in real-time. These systems can detect and correct deviations in the material flow, ensuring that each piece is formed correctly and reducing the incidence of waste.

In addition, automated roll changing and lubrication systems further reduce waste by minimizing downtime and ensuring that the equipment operates efficiently. These systems allow manufacturers to maintain a consistent production rate, reducing the amount of scrap material generated and increasing overall material utilization.

Conclusion

Heavy gauge roll forming equipment has undergone significant innovations that have greatly improved material utilization in manufacturing. Precision engineering, adaptability, and automation have all played crucial roles in reducing waste, increasing productivity, and improving product quality.

As manufacturers continue to seek ways to optimize their operations, the adoption of advanced roll forming equipment will be essential. By embracing these innovations, manufacturers can maximize the yield and quality of their products, reduce material waste, and ultimately drive profitability and growth.