Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 23, 2024 Visit:117 Source:ZCM Roll Forming Machine

In the realm of manufacturing, innovation is the lifeblood that drives progress and efficiency. A leading manufacturer of heavy gauge roll forming machines has embraced this principle, pushing the boundaries of traditional technology to deliver cutting-edge solutions that meet the evolving needs of the industry. These innovations not only enhance the capabilities of the machines but also improve productivity, precision, and overall performance.

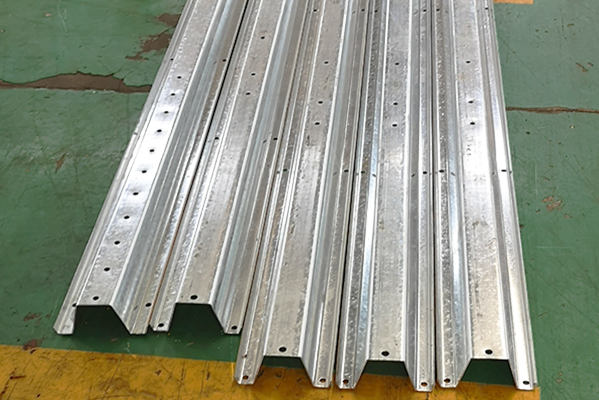

Heavy gauge roll forming machines are pivotal in the production of a wide range of industrial components, from automotive parts to construction materials. Traditional machines have served the industry well, but with the increasing complexity of manufacturing requirements, there is a growing need for machines that can offer more flexibility, accuracy, and efficiency. The leading manufacturer has responded to this challenge with a series of innovative advancements.

One of the most significant innovations is the integration of advanced automation systems. These systems enable the machines to operate with greater precision and consistency, reducing the margin for error and enhancing the quality of the finished products. By automating key processes, the manufacturer has also been able to streamline production, reducing downtime and increasing throughput.

Another key innovation is the development of new materials and technologies that enhance the durability and performance of the machines. The manufacturer has invested heavily in research and development, leading to the creation of stronger, more wear-resistant components that can withstand the rigors of heavy-duty manufacturing. This has not only extended the lifespan of the machines but also reduced maintenance costs and downtime.

The manufacturer has also focused on improving the user experience. By incorporating intuitive control systems and user-friendly interfaces, the machines are now easier to operate and maintain. This has led to increased productivity and reduced training costs for operators. Additionally, the manufacturer offers comprehensive support services, including technical assistance and troubleshooting, ensuring that customers can maximize the potential of their machines.

In addition to these innovations, the manufacturer has also introduced new machine designs that cater to specific industry needs. For example, machines tailored for the automotive industry can now produce complex shapes and profiles with high precision, meeting the stringent quality standards required by this sector. Similarly, machines designed for the construction industry can handle thicker materials and produce larger components, meeting the demands of infrastructure projects.

The manufacturer's commitment to innovation extends beyond the machines themselves. By fostering a culture of continuous improvement and collaboration with customers, the company has been able to stay ahead of industry trends and anticipate future needs. This proactive approach has led to the development of new technologies and solutions that not only meet current requirements but also pave the way for future advancements.

In conclusion, the leading manufacturer of heavy gauge roll forming machines has demonstrated its commitment to innovation by delivering a range of cutting-edge solutions that enhance the capabilities and performance of its machines. These innovations not only meet the evolving needs of the industry but also set a new standard for quality, productivity, and efficiency. As the manufacturing landscape continues to evolve, the manufacturer is well-positioned to lead the way with its innovative approach to heavy gauge roll forming technology.