Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 23, 2024 Visit:210 Source:ZCM Roll Forming Machine

The aerospace industry has always been at the forefront of technological innovation, pushing the boundaries of what is possible in engineering and manufacturing. Among the various tools and machines that drive this industry, heavy gauge roll forming machines have played a crucial role. Recently, these machines have seen a notable market expansion within the aerospace sector, driven by several key factors.

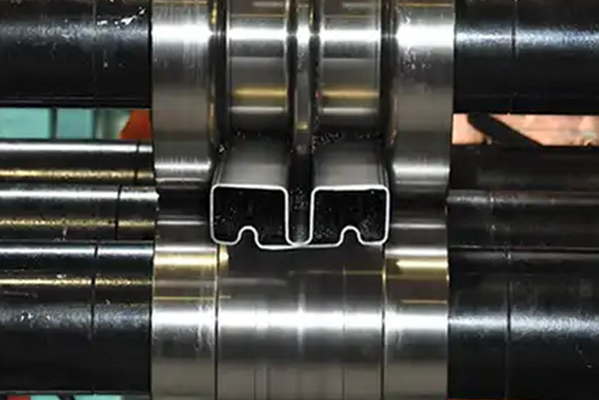

One of the primary reasons for this expansion is the increasing demand for lightweight yet strong materials in aerospace applications. Heavy gauge roll forming machines are capable of shaping thick metal sheets into complex geometries, which are often required for structural components in aircraft and spacecraft. By using these machines, manufacturers can produce parts that are both lighter and stronger, contributing to improved fuel efficiency and enhanced overall performance of aerospace vehicles.

The growing trend of customization in the aerospace industry has also fueled the market expansion for heavy gauge roll forming machines. With the rise of new aircraft models and the need for tailored solutions, manufacturers are increasingly relying on these machines to produce custom parts that meet specific design requirements. The ability to form metal sheets into intricate shapes and sizes makes heavy gauge roll forming machines an ideal choice for this purpose.

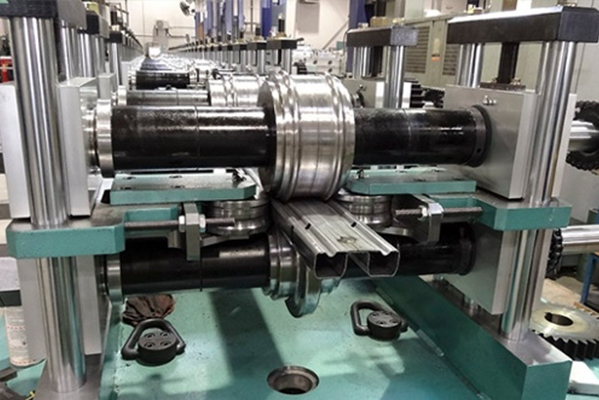

Furthermore, advancements in technology have made heavy gauge roll forming machines more efficient and reliable, which has contributed to their growing popularity in the aerospace sector. Modern machines are equipped with advanced automation and control systems that enable them to operate with unprecedented precision and consistency. This has led to improved quality and reduced production times, making them more attractive to aerospace manufacturers who are constantly striving to optimize their production processes.

The increasing focus on cost-efficiency in the aerospace industry has also played a role in the market expansion for heavy gauge roll forming machines. With competition intensifying and margins tightening, manufacturers are looking for ways to reduce costs while maintaining high standards of quality. Heavy gauge roll forming machines offer a cost-effective solution for producing complex structural components, as they can be used to form multiple parts simultaneously, reducing labor costs and waste.

In addition to these factors, the global aerospace market is expected to continue growing in the coming years, driven by increasing demand for air travel, advancements in space exploration, and the need for more efficient and sustainable aircraft. This market growth will create new opportunities for heavy gauge roll forming machine manufacturers, as aerospace companies will need to invest in advanced manufacturing equipment to stay competitive.

As the aerospace industry evolves, it is likely that we will see further innovation in heavy gauge roll forming machines. Manufacturers will continue to develop new technologies and processes that enhance the capabilities and efficiency of these machines, enabling them to produce even more complex and high-performance parts. This ongoing innovation will not only drive market expansion but also contribute to the overall growth and success of the aerospace sector.

In conclusion, the market for heavy gauge roll forming machines in the aerospace sector is experiencing significant expansion, driven by the increasing demand for lightweight yet strong materials, customization, technological advancements, cost-efficiency, and market growth. With these factors in place, it is likely that we will see continued growth and innovation in this area, further solidifying the role of heavy gauge roll forming machines in the aerospace industry.