Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 16, 2024 Visit:68 Source:ZCM Roll Forming Machine

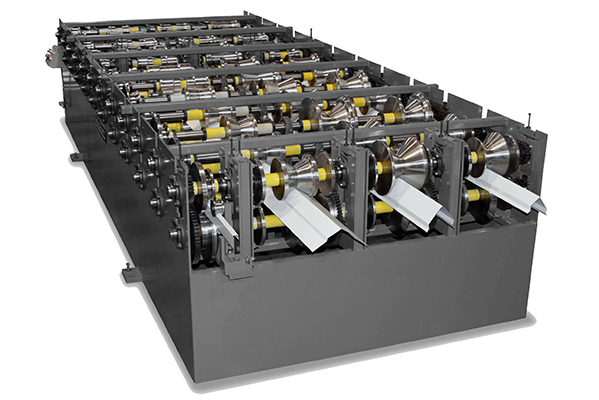

In the vast world of manufacturing, the rolling forming machine, as an efficient and precise forming equipment, is becoming an important force in promoting industrial upgrading with its unique process advantages and wide application potential. In recent years, with the continuous advancement of technology and the diversified demands of the market, the application fields of rolling forming machines have continued to expand. They not only play an irreplaceable role in traditional manufacturing, but also demonstrate infinite possibilities in emerging industries.

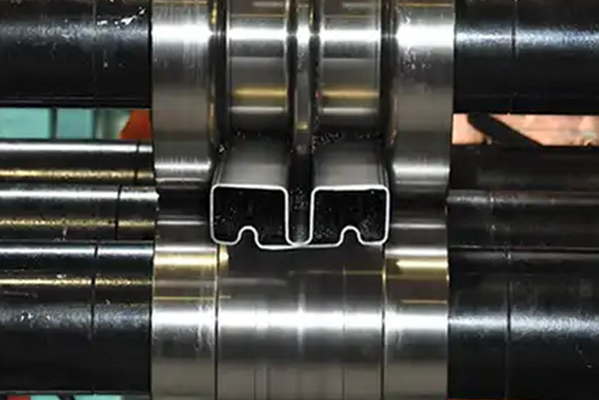

Rolling forming technology applies continuous and uniform pressure to materials through rollers, causing them to undergo plastic deformation and achieve the desired shape and size. This molding method not only has a simple process and high efficiency, but also ensures product consistency and accuracy. Therefore, it has been widely used in various fields such as metal processing, plastic molding, and ceramic manufacturing.

In the field of metal processing, rolling forming machines are widely used in the manufacturing of pipes, profiles, automotive parts, etc. Through precise rolling technology, metal products with stable dimensions and smooth surfaces can be produced, meeting the market's demand for high-quality and high-precision products. At the same time, roll forming technology can effectively reduce material waste, lower production costs, and improve production efficiency.

The plastic molding field is also a place where roll forming machines have shown their skills. With the widespread application of plastic products in daily life and industrial production, the requirements for the quality and accuracy of plastic products are also increasing. The rolling forming machine can produce various complex shaped and precisely sized plastic products, such as home appliance casings, automotive interior parts, etc., by precisely controlling the pressure and temperature of the rollers. In addition, roll forming technology can also achieve lightweight design of plastic products, reduce production costs, and improve market competitiveness.

In the field of ceramic manufacturing, rolling forming machines also play an important role. Ceramic materials have a wide range of applications in aerospace, electronic information, biomedicine, and other fields due to their unique physical and chemical properties. Rolling forming technology can precisely control the shape and size of ceramic materials while maintaining their excellent performance. This makes the rolling forming machine irreplaceable in the field of ceramic manufacturing.

In addition to the traditional fields mentioned above, rolling forming machines are constantly expanding into new application areas. For example, in 3D printing technology, roll forming technology is used in the post-processing stage to improve the accuracy and surface quality of printed parts. In the field of new energy, rolling forming machines are used to manufacture key components such as solar panels and lithium-ion batteries, providing strong support for the development of the new energy industry.

The reason why rolling forming machines can be widely used in multiple fields and continuously expand into new application areas lies in the continuous innovation and upgrading of their technology. With the continuous development of intelligent and automated technology, rolling forming machines are moving towards higher efficiency, intelligence, and flexibility. In the future, rolling forming machines will demonstrate their unique advantages in more fields, contributing more to the transformation, upgrading, and high-quality development of the manufacturing industry.

In summary, the rolling forming machine is becoming an important force in promoting the development of the manufacturing industry with its wide range of application fields and continuous innovation power. With the continuous advancement of technology and the diversified demands of the market, the application fields of rolling forming machines will continue to expand, injecting new vitality into the prosperous development of the manufacturing industry