Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 13, 2024 Visit:84 Source:ZCM Roll Forming Machine

In the dynamic landscape of manufacturing, efficiency is a cornerstone of competitiveness. As businesses strive to meet market demands, reduce costs, and enhance product quality, the role of innovative technology becomes increasingly critical. Among the various technological advancements, roll forming machine innovations have emerged as a significant driver of manufacturing efficiency. These innovations have transformed the process of shaping metal into complex profiles, enabling manufacturers to achieve higher throughput, reduced waste, and streamlined operations.

One of the most transformative innovations in roll forming machines is the integration of advanced automation systems. Traditional roll forming machines required significant manual intervention, which not only slowed down production but also introduced variability and errors. Modern roll forming machines, however, are equipped with sophisticated automation systems that can handle a wide range of tasks, from material loading and unloading to roll adjustment and process monitoring. These systems significantly reduce the need for human intervention, thereby minimizing downtime and enhancing overall efficiency.

Another key innovation is the development of intelligent control systems. These systems leverage advanced algorithms and real-time data analysis to optimize the roll forming process. By continuously monitoring machine parameters and material behavior, the control systems can adjust the rolling forces, speeds, and temperatures to maintain optimal forming conditions. This predictive and adaptive capability ensures that the process remains stable and consistent, reducing the risk of defects and improving product quality.

The incorporation of high-precision sensors and feedback mechanisms has also played a crucial role in boosting manufacturing efficiency. These sensors provide manufacturers with real-time data on various aspects of the roll forming process, such as material flow, roll positioning, and temperature distribution. By analyzing this data, engineers can identify potential issues and make informed adjustments to the process, thereby minimizing waste and maximizing productivity.

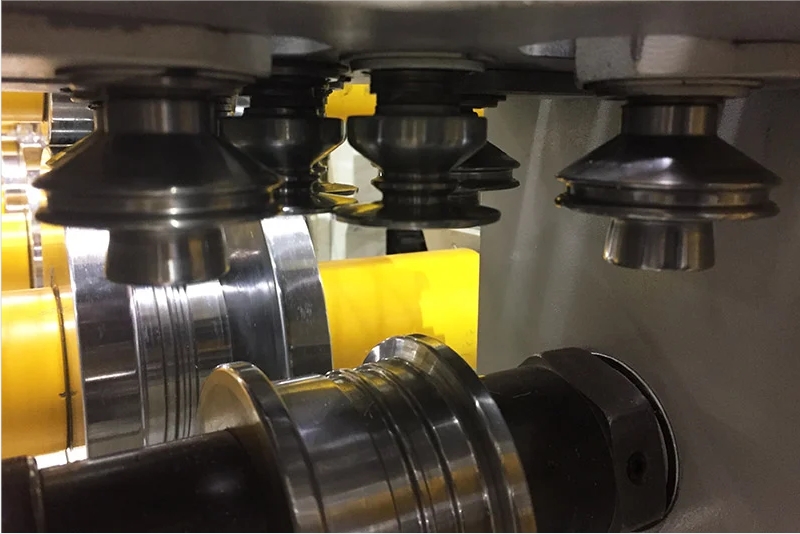

Furthermore, the evolution of multi-axis roll forming machines has revolutionized the manufacturing of complex shapes and profiles. Traditional roll forming machines were limited to a single axis of movement, which restricted the types of shapes they could produce. Modern multi-axis machines, however, offer greater flexibility and precision. By incorporating rolls that can move in multiple directions, manufacturers can achieve intricate forming sequences and produce a wider range of shapes with higher accuracy and efficiency.

In addition to these technological advancements, manufacturers have also focused on improving the overall design and functionality of roll forming machines. By optimizing the machine layout, enhancing roll materials, and incorporating energy-efficient components, manufacturers have been able to reduce maintenance requirements, extend machine lifespan, and improve overall system performance. These improvements not only contribute to higher efficiency but also enhance the safety and ergonomics of the manufacturing process.

The combined effect of these innovations has been a significant boost in manufacturing efficiency. Manufacturers are now able to produce roll-formed products with shorter lead times, reduced waste, and higher quality. This level of efficiency is crucial in today's competitive market, where customers demand faster delivery times, lower costs, and superior product performance.

Moreover, the efficiency gains have led to a more sustainable manufacturing process. By minimizing waste and maximizing material utilization, manufacturers can reduce their environmental footprint and contribute to a more sustainable future. Although this article does not focus on environmental aspects, it is worth noting that efficiency improvements often have positive environmental implications.

In conclusion, roll forming machine innovations have played a pivotal role in boosting manufacturing efficiency. By integrating advanced automation systems, intelligent control systems, high-precision sensors, and multi-axis capabilities, manufacturers are now able to achieve higher throughput, reduced waste, and streamlined operations. As these innovations continue to evolve, we can expect to see even greater gains in efficiency, driving competitiveness and innovation in the manufacturing industry.