Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 12, 2024 Visit:233 Source:ZCM Roll Forming Machine

In the realm of manufacturing, precision is paramount. It is the cornerstone of quality, reliability, and customer satisfaction. Among the various processes that contribute to precision manufacturing, roll forming stands out as a versatile and efficient method for shaping metal into intricate profiles. Recent enhancements in roll forming machine technology have significantly improved production precision, enabling manufacturers to meet the most demanding specifications and deliver exceptional results.

One of the key enhancements in roll forming machines is the incorporation of advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software. These systems provide manufacturers with the ability to design and simulate roll forming processes with unparalleled accuracy. By using CAD/CAM software, engineers can predict material behavior, optimize roll configurations, and refine manufacturing parameters before the actual production begins. This predictive capability minimizes trial and error, reduces material waste, and ensures that the final product meets or exceeds specified tolerances.

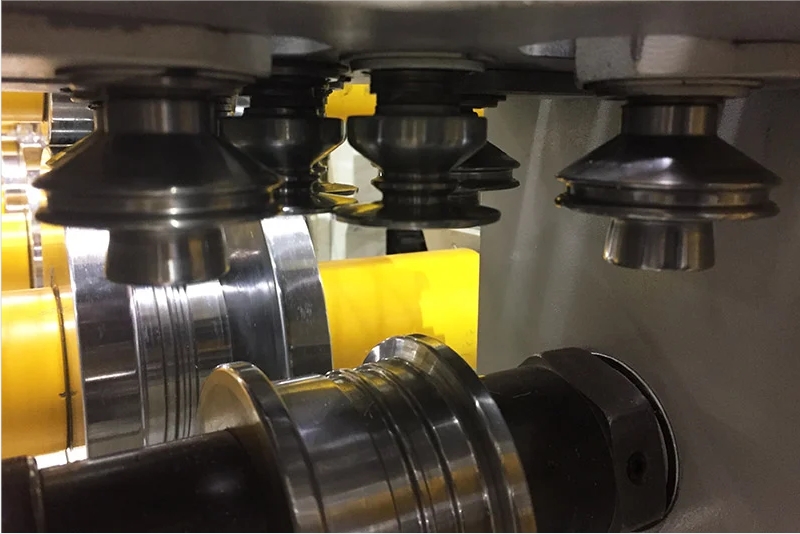

Another significant enhancement is the integration of precision sensors and feedback systems. Modern roll forming machines are equipped with sensors that monitor the forming process in real-time, providing data on material flow, roll positioning, and temperature. This data is fed back into the control system, which adjusts the machine parameters to maintain consistent forming conditions. The result is a more precise and controlled process, with reduced variability and improved repeatability.

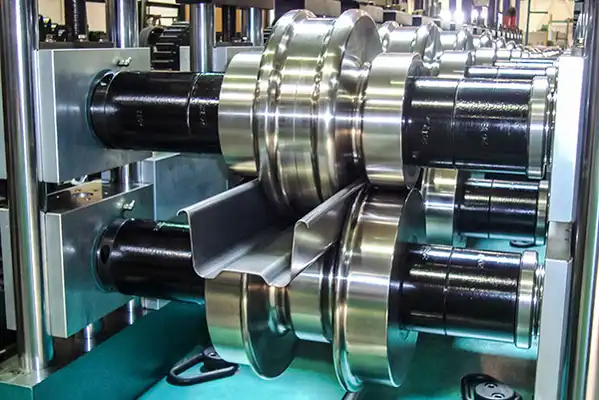

The development of multi-axis roll forming machines has also played a crucial role in improving production precision. Traditional roll forming machines typically operate along a single axis, limiting the complexity of the shapes they can produce. Multi-axis machines, however, offer greater flexibility and versatility. By incorporating vertical and horizontal rolls, as well as adjustable roll spacing, multi-axis machines can achieve intricate forming sequences that were previously impossible. This capability enables manufacturers to produce a wider range of shapes and profiles with higher precision and fewer defects.

In addition to these technological enhancements, manufacturers have also focused on improving the mechanical and electrical components of roll forming machines. By using high-precision bearings, motors, and drives, manufacturers can ensure that the machines operate smoothly and consistently. These components reduce vibration and wear, leading to longer machine lifespan and better overall performance.

The combined effect of these enhancements has been a significant improvement in production precision. Manufacturers are now able to produce roll-formed products with tighter tolerances, smoother surfaces, and fewer defects. This level of precision is crucial in industries such as automotive, aerospace, and electronics, where the performance and reliability of the final product depend heavily on the accuracy of the manufacturing process.

Moreover, the improved precision has led to increased efficiency and cost savings. By reducing waste and minimizing the need for secondary operations, manufacturers can streamline their production processes and reduce overall costs. This, in turn, enhances competitiveness and enables manufacturers to better serve their customers.

In conclusion, the enhancements in roll forming machine technology have significantly improved production precision. By incorporating advanced CAD/CAM software, precision sensors, multi-axis capabilities, and high-quality components, manufacturers are now able to produce roll-formed products with unprecedented accuracy and reliability. As these technologies continue to evolve, we can expect to see even greater improvements in production precision, driving innovation and competitiveness in the manufacturing industry.