Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 23, 2024 Visit:198 Source:ZCM Roll Forming Machine

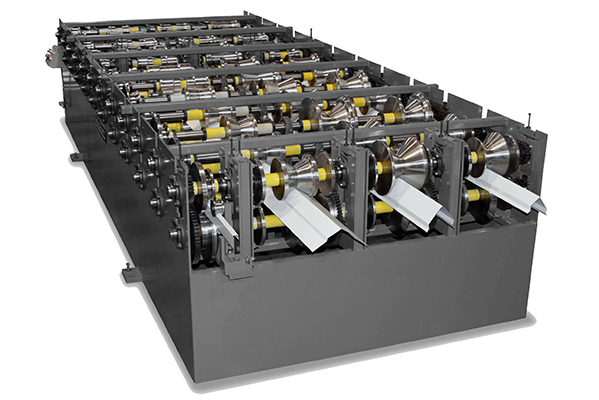

In the realm of industrial manufacturing, heavy gauge roll forming machines have been a staple for decades. Their ability to shape and form thick metal sheets into various shapes and sizes has made them indispensable in sectors such as automotive, construction, and aerospace. Recently, technological advancements have significantly elevated the efficiency of these machines, transforming them into even more powerful and versatile tools.

One of the most notable advancements is the integration of advanced automation systems into heavy gauge roll forming machines. These systems enable the machines to operate with unprecedented precision and consistency. By using sensors and computer algorithms, the machines can now monitor and adjust their operations in real-time, ensuring that each formed component meets the specified dimensions and specifications. This automation not only reduces human error but also enhances productivity by allowing the machines to run continuously without the need for constant manual intervention.

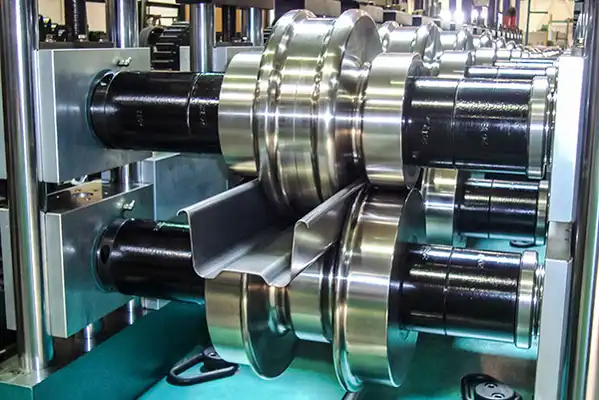

Moreover, the advent of high-precision tooling has further improved the efficiency of heavy gauge roll forming machines. Traditional tooling used in these machines often required frequent adjustments and replacements due to wear and tear. However, modern tooling is made from high-quality materials that are more durable and resistant to wear. This means that the machines can operate for longer periods without needing maintenance, which reduces downtime and increases overall efficiency.

In addition to automation and tooling advancements, the development of intelligent control systems has also had a significant impact on the efficiency of heavy gauge roll forming machines. These systems use advanced algorithms to optimize the machine's operation based on the specific requirements of the job. For instance, they can adjust the speed, force, and temperature of the roll forming process to ensure that the metal is formed to the desired shape without causing excessive strain or damage. This intelligent control not only improves the quality of the finished product but also reduces energy consumption and waste.

Another technological advancement that has elevated the efficiency of heavy gauge roll forming machines is the use of digital twins. A digital twin is a virtual representation of the machine that simulates its operation in real-time. By using digital twins, manufacturers can predict and optimize the machine's performance before it is even used in production. This enables them to identify potential issues and make necessary adjustments before they lead to costly delays or defects.

The integration of these technological advancements has not only improved the efficiency of heavy gauge roll forming machines but also expanded their capabilities. Modern machines can now handle a wider range of materials and thicknesses, making them more versatile and adaptable to different industrial applications. This versatility has opened up new opportunities for manufacturers to innovate and create new products that meet the evolving needs of the market.

In conclusion, technological advancements have significantly enhanced the efficiency of heavy gauge roll forming machines. By integrating automation, high-precision tooling, intelligent control systems, and digital twins, manufacturers have been able to improve the precision, consistency, and productivity of these machines. As the industrial manufacturing sector continues to evolve, it is likely that we will see even more advancements in this area, further elevating the efficiency and capabilities of heavy gauge roll forming machines.